Abstract

Among all renewable energy resources wind energy is the more widely using form. The highly

fluctuating behaviour of wind rises the need for an optimized blade design for various wind

energy capturing devices for ensuring maximum usable power output. In this work, based on the

real experimental data of an already established wind turbine (Nordtank 150kW) a new optimized

design is generated and compared with results of existing literatures. The objective function of

this optimization was to maximize the Annual Energy Production (AEP) and to minimize the Blade

Mass. The genetic algorithm optimization method employed here allowed a means of tackling the

multi-objective problem such that the aerodynamic characteristics of the blade can be optimized

for a particular wind speed range with structural constraints.

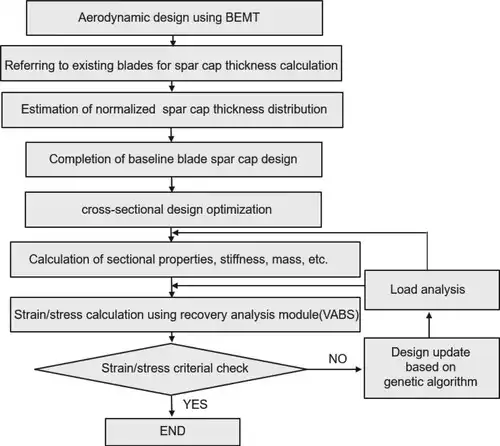

This problem of optimization is done by using an open source horizontal axis wind turbine

optimization code developed by National Renewable Energy Laboratories (NREL). The aerodynamic

optimization was done with Blade Element Momentum theory and structural optimization was done based

on the Euler-Bernoulli beam theory. In optimization the actual single airfoil type used is replaced

with a span wise arrangement of 3 different airfoils. The resulted blade design from optimization

offered substantial improvements in aerodynamics of blade and hence by consistent performance within

the range of design points than the reference design.

Related Work

In this work the aerodynamic shape and blade mass of Nordtank 150 kW wind turbine are modified

and optimized based on multi objective genetic algorithm and blade element theory. Optimization

studies are performed to maximize the power production and to minimize the blade mass. Here the

design variables considered are pre-twist of blade, chord length, percentage thickness and shell

thickness of the blade. Here the optimization study is having limits and penalties of wind speed

range, rotor rpm range, maximum power value, maximum strain value and cavitation considerations.

The various steps involved in this optimization study includes selection of reference turbine

data, design of reference turbine blade, multi-objective genetic algorithm optimization, design

of optimized blade and comparison study of both aerodynamic and structural variables of

reference blade with optimized blade.

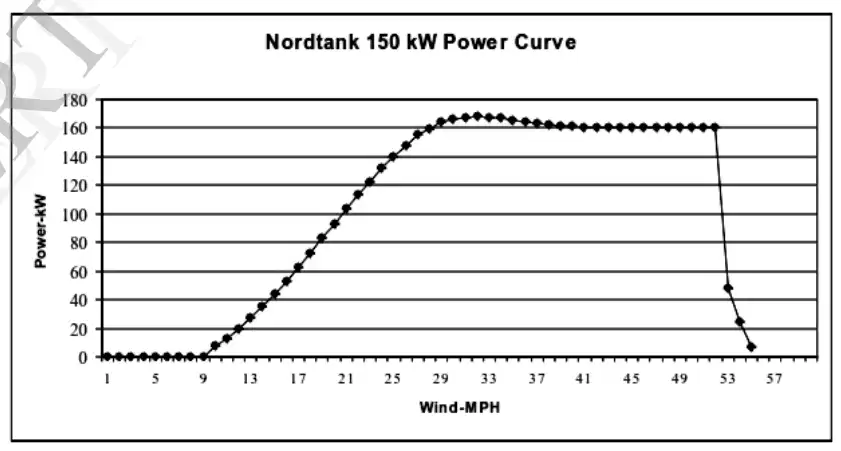

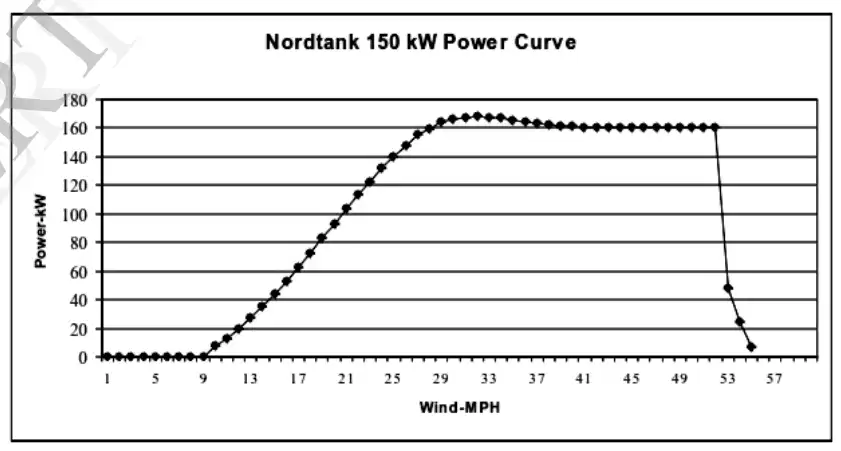

Nordtank 150 kW wind turbine is selected as the reference turbine for this optimization.

Nordtank series wind turbines are invented by Nordtank Energy Group, Denmark in the year of 1988

and this Nordtank 150 kW wind turbine is first installed in 1989. As a part of technology

advancement the initial design was modified a number of times and at last it is completely

retrofitted in 2006. The intention behind the selection of this Nordtank 150 kW wind turbine is

to reduce the computational complexity which may arise while doing analysis on large wind

turbines having power output in megawatts

The technical data of Nordtank 150 kW is given below,

-

Tower – Hub height -32.5 m, Material – Galvanized tubular steel, single section with access

doors at top and bottom, Safety – Inside tower ladder, climbing cable, no slip and lockable

doors.

-

Component Weights - Tower - 10,500 kg, Nacelle - 3,900 kg, Blades - 3 x 790 kg.

-

Rotor - 3 Bladed, upwind, fixed pitch, stall regulated., Diameter - 24.6 m, Swept Area -

475m2 , Material - Glass fiber reinforced polymer, Wing profile type - NACA 63 Airfoil

family.

-

Drive Train - Gearbox - Flender, Tyskland or Jahnel / kestermann / Tyskland. (Gear

ratio1:40), Power - 165 kW, Oil volume - 60 liters, Speed - 38 to 1520 rpm.

-

Generator - Made - ABB Motors , Finland or EMOD Germany, Type - Asynchronous, 4 Pole, Rating

- 165 kW, 1520 rpm, 400 V, 50 Hz, Certification - ISO 9002

-

Operational Data - Cut-in wind speed - 4 m/s, Rated windspeed - 12 m/s, Cut-out wind speed -

25 m/s.

-

Blades - Fibreglass reinforced polyester, Rotor speedNominal 38.1 rpm, Tip speed - Nominal

49 m/s.

-

Controller and Yaw System - Type - KK Controller, Microprocessor system with data logger,

Cut-in system - Soft by Thyristors w/PLC, Yaw - Slide bearing 2 yaw gears / Active Yaw

brakes, Drive - Yaw gears and dual electric drives, Control - Active yaw / wind vane ,

speed.

Based on the data sheet the Nordtank 150 kW wind turbines original blade parameters are defined

and basic design is done in Qblade blade design software. The blade design is shown below

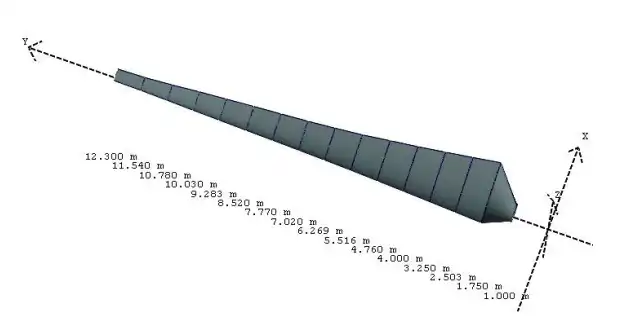

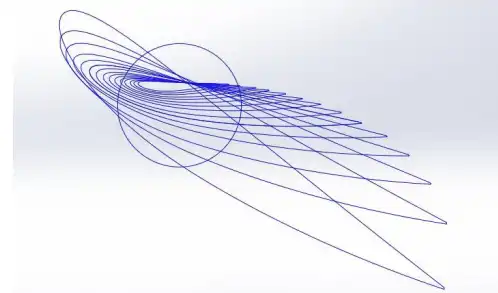

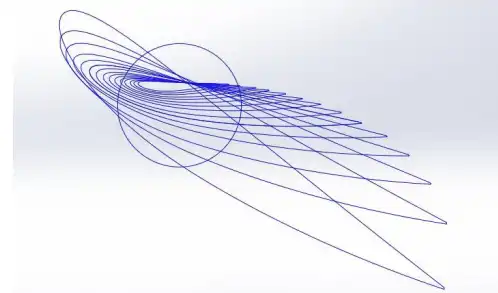

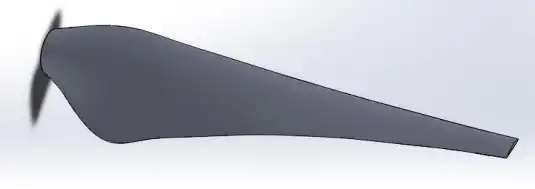

After the design in Qblade the coordinate file for the total blade is generated and that single

coordinate file is again subdivided into coordinate files of different airfoils at different

span-wise stations. Then those coordinate files of airfoils at various stations are imported

into Solidworks using the curve through xyz points option for design and the airfoils at various

stations can be aligned as shown below

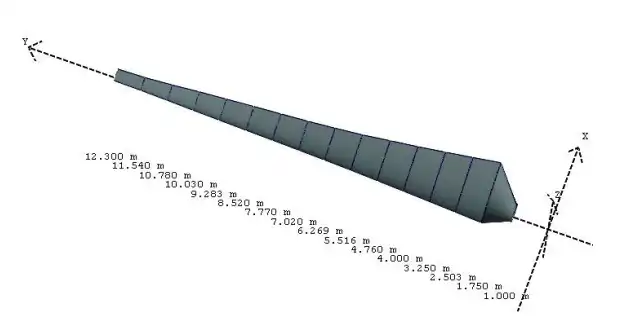

Using the lofting feature the airfoil curves at various stations are lofted to create the

complete blade span as shown below

Multi Objective Design Optmisation Using Genetic Algorithm.

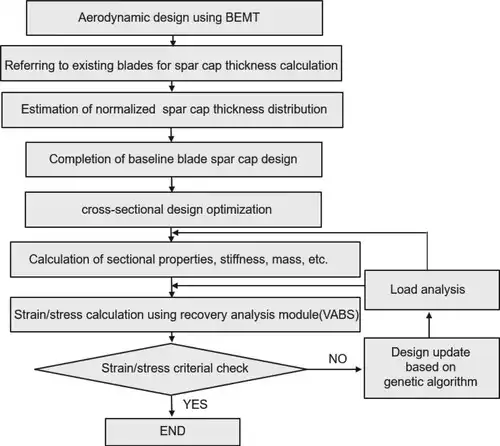

The multi-objective design optimization of wind turbine blade with Annual energy production and

Blade mass as the objective functions is carried out using the Horizontal Axis Rotor Performance

Optimization (HARP Opt.) code developed by NREL. The HARP Opt. code works with MATLAB Genetic

Algorithm Optimization Toolbox and Statistics Toolbox. It also uses the blade element momentum

(BEM) theory model to design horizontal axis turbine rotors.

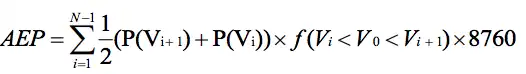

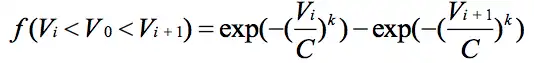

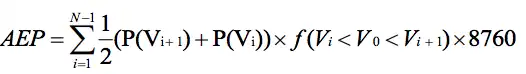

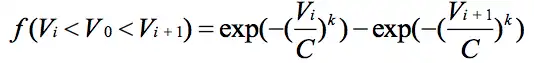

The optimization objectives are to maximize the turbine’s annual energy production (AEP) and

minimize the blade mass. Annual energy production is calculated using the Weibull flow

distribution. Maximum power is bounded, and maximum power point tracking (MPPT) is a combined

objective with AEP. AEP is calculated using the following equation.

Where c is the scale parameter, k is the shape parameter and V is the wind speed.

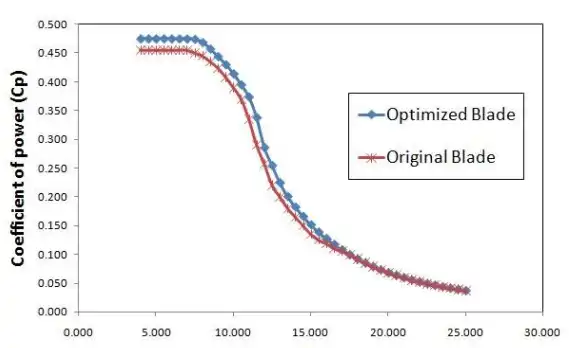

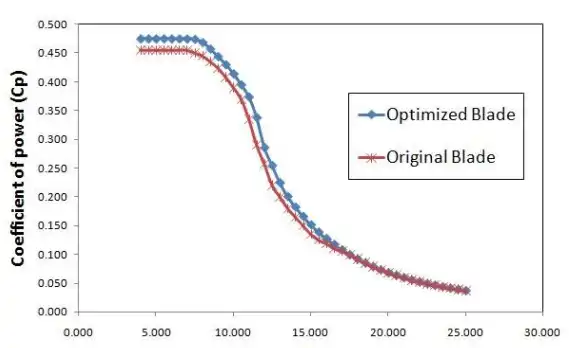

Here the performance optimization has done in terms of the coefficient of performance (Cp) value

. The coefficient of performance can also be defined as the ability of a wind turbine to develop

power. The Cp curve for the original blade is generated based on the available technical data

sheets of Nordtank 150 kW and Cp values for the optimized blade can be obtained from the GA

optimization results. The coefficient of performance (Cp) value is found increased during

optimization.